Conventional machining relies on metalworking fluids to provide several key areas of performance. Metalworking fluids decrease cutting forces, reduce cooling at the point of cut and effectively wash chips away from the cutting zone. Water based fluids require ongoing maintenance and monitoring. The service life of most fluids is limited, resulting in down time and additional disposal costs and impact the environment.

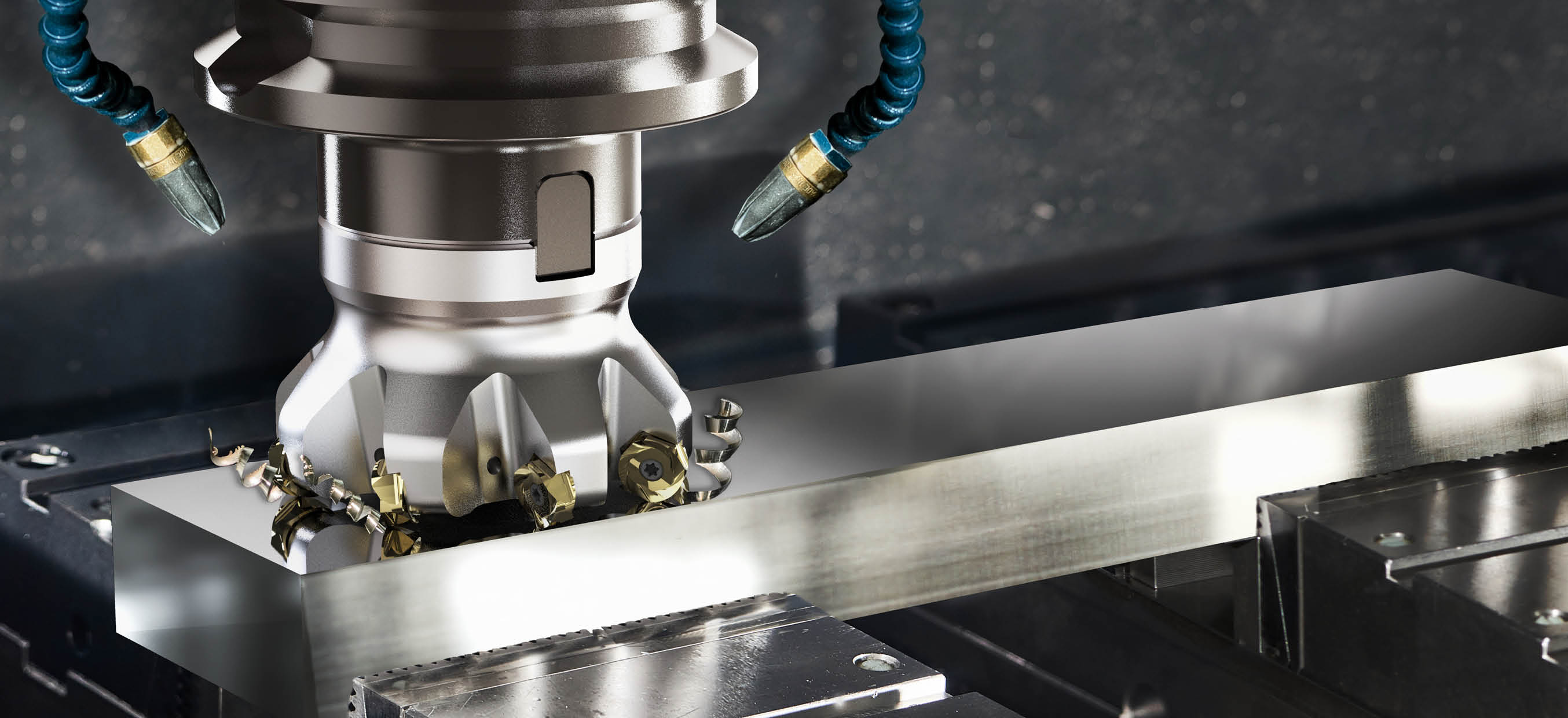

MQL (Minimum Quantity Lubrication) provides an alternative option to traditional metalworking fluids. It is a process of applying a controlled amount of lubricant, utilizing compressed air as the propellant. The fluid can be directed toward the precise location, minimizing usage to approximately 5ml - 50ml per process hour. The lubricant creates a bond to the metallic surface providing exceptional lubricity and cooling properties.

MQL provides the following benefits

- Reduces fluid and water usage.

- Cleaner parts and work areas as compared coolant to flood.

- Higher feeds and speeds are possible resulting in higher production rates.

- Eliminates use of additives and disposal costs associated with conventional coolant.

- Chips produced in the machining process are nearly dry, increasing the value.

- Improved visibility of the work piece and machine.

Trade-offs of using MQL

- Investment and installation of an applicator is required for each machine tool running MQL.

- MQL will not move all chips from the tool interface to the conveyor of machine tool.

- MQL provides limited corrosion protection on the parts and machine tool.

- Nozzles used for the MQL process need to be positioned extremely close to the point of cut.

- Nozzles can be easily moved by operators or chip stringers.

Typical types of MQL fluid

- Vegetable based

- Synthetic esters

Chem Arrow manufactures a high-performance, synthetic ester MQL product called ArrowMist 5000. This product is designed to run extremely clean, providing exceptional tool life and surface finish. This multi-metal fluid can run in a wide variety of applications including sawing, turning, milling and drilling.

Contact your local Chem Arrow distributor or Chem Arrow representative to see if MQL is right for your application.